TEL:

0373-6372968-

CONTACT US

Mingyang Machinery Equipment

TEL:0373-6372968 6372969

FAX:0373-5755777

CONTACTS:Mr. Zhu

PHONE:159 0303 3385

E-MAIL:1139537703@qq.com

ADDRESS:GuGuZhai town industry gathering area, Xinxiang city Henan province

BUS LINE:Take a bus to Xinxiang City for pick-up and delivery!

UPDATA:2019-05-10

HITS:8282次

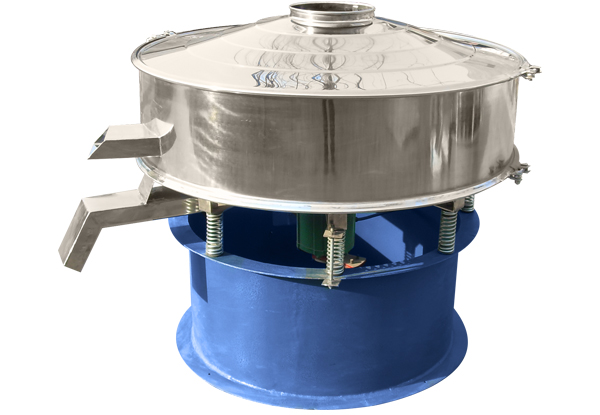

PECULIARITY: Slurry vibrating ...

Product Description:

Myzp series intermediate frequency sieve is a special vibrating screen,it is based on the original slurry sieve to transform , through the technical improvements and a large number of experiments.This product owns single-layer grid structure,the up frame is heightening open type,the bottom frame doubled as vibrating screen,has some characteristics of large output,low power consumption,fast slag discharge etc.the vibration motor uses specially designed energy-saving motors with the dial,than the same model sieving equipment saving about 30% energy.Slurry filter screen(Plus edge type rotary vibration sieve) increased the feed inlet on the basis of the ordinary rotary vibration screen,designed for screening specific materials,ceramic specially used vibration screen,made a corresponding improvement on the adjustment of the motor flange and on the vibration motor counterweight block,thereby enabling the vibration screening is ideal for slurry filtration,not only does the filtration efficiency obtain a very large increase ,but also reduces the friction of the material and the mesh,that greatly improves the screen’s service life

Application:

Applicable to the filtration of the yeast mixture, glaze and other various liquids .

Product Features:

1,The up frame is heightening open type,increase the randomness of the installation,and easily observed the working condition through the mesh.

2,The special design of the bottom frame ,adopts the advanced processing technology to optimize the whole structure,makes the installation easier.

3,The performance of slag discharge is good, improve the utilization of mesh ,increase the amount of processing.

4, changing and cleaning the mesh is more convenient, and improve the work efficiency.

5,The design of energy-saving motor, small energy consumption, low noise.

Technical parameters:

Model

Nominal diameter

(mm)

Diameter of

screen surface

(mm)

Effective area of screen surface

(m³)

Max feeding size

(mm)

Vibration times

(Rpm)

Power

(KW)

XZS-400

400

340

0.09

<10

1500

0.18

XZS-600

600

530

0.22

<10

1500

0.25

XZS-800

800

720

0.4

<20

1500

0.55

XZS-1000

1000

900

0.63

<20

1500

0.75

XZS-1200

1200

1100

0.95

<20

1500

1.1

XZS-1500

1500

1400

1.5

<20

1500

2.2

XZS-1800

1800

1710

2.3

<30

1500

3

XZS-2000

2000

1910

2.86

<30

1500

4

The official website of our company's related equipment, please check and browse.:

http://www.myzhendongshai.com/(Mixer website)

http://www.zhendongshai-my.cn/index.php(Pneumatic conveying website)

http://www.mingyangsf.com/(Comprehensive website

| Last article: | Standard testing sieve--Sample sieve |

| Next article: | Linear vibrating screen |

Yugong Network Security, No. 41072102000531

Yugong Network Security, No. 41072102000531